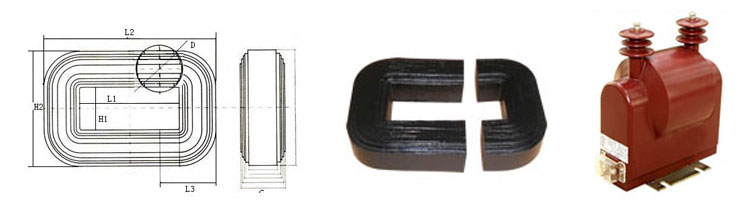

Stepped core

Characteristics

Made of high magnetic-flux, low iron-loss silicon steel sheets, wound in varying widths creating steps. Produced using advanced technologies: high vacuum annealing, vacuum immersing, and baking paint on within a protective atmosphere. This type of core has single-phase and three-phase points. Compared to laminated iron cores, Step Wound Cores are smaller, have lower air cut losses, lower low to no-load losses, create less noise, and so on, giving these cores greater advantages in small to medium-sized distribution transformers.

Applications

Distribution Transformers / Power Transformers / Transformers / Reactors / Voltage Regulators / Special Transformers / etc.

Product Application

Technical Parameter

| Model | Length*Wide(Inside) L1*H1 |

Length*Wide(Outside) L2*H2 |

Diameter φ D |

thick in each stack B(B1,B2,B3..) |

Core width per stage C(C1,C2,C3..) |

|---|---|---|---|---|---|

| JDZ9-10 | 150*67 | 250*167 | 59 | 50(20,33,42,50) | 30,40,48,55 |

| JDZX9-10 | 136*52 | 260*176 | 69 | 60(22,40,51,62) | 30,45,55,65 |

| JDZX6-35 | 155*100 | 295*240 | 80 | 70(24,44,60,70) | 35,50,65,75 |

| JDZX9-35 | 136*106 | 260*230 | 70 | 62(22,40,51,62) | 30,45,55,65 |

| JDZX11-20 | 160*78 | 290*208 | 80 | 65(24,44,56,65) | 45,55,65,75 |

| JDZX16-20Q | 170*80 | 330*240 | 85 | 80(24,45,58,70,80) | 25,45,60,70,80 |

| JDZXW3-25 | 118*106 | 242*230 | 70 | 62(22,40,51,62) | 35,45,55,65 |